The hot stamping process is a very common surface finishing process, which can transfer of gold, silver and

other colors of electro-aluminum materials on the prints, so as to improve the surface of the prints.

The traditional hot stamping machine are divided into two types, one is a hot stamping device installed on a semi-automatic die-cutting device,which requires manual feeding, hot stamping and manually collection, the speed is quite slow and the format is limited, during the operation, it needs to be handled by hand, thus causing the serious safety problems.

Other automatic platen press or rotary press die cutting and stamping machine for card paper boxandlabel, suitable for visual position and mass

production as well as the thin printing products, but it needs toinvestin a lot.

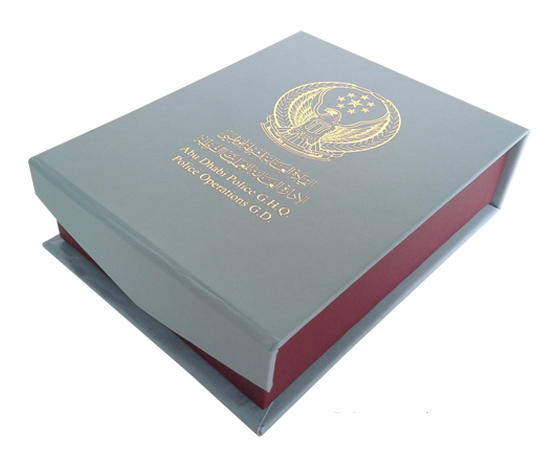

So for the thick case for the hardcover book and packaging box and different

stamping sizes, how tomeet this kind of stamping requirements?

In 2013, ST had launched the new automatic hot stamping machine,which is usedfor stamping on the finished hard cases for hardcover books and packaging boxes.

The whole machine is driven by cam and the stamping size can be adjusted flexibly, so

it is suitable for different case format, compared with the other stamping machine, it has obtained the below advantages:

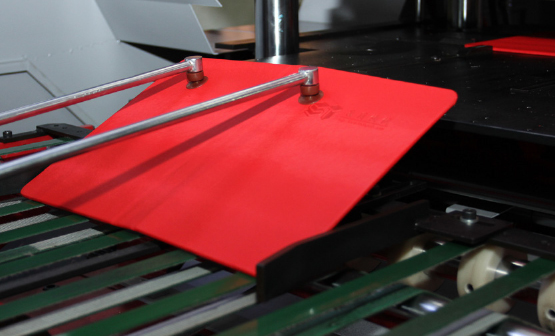

Automatic Feeding and Collecting

Automatic case feeding and collecting can be suitable for different thickness cases,

such as case with sponge, case with cloth cover and PU. While improving the production efficiency,

it can also avoid the security problems.

Rotary Feeding Device

Hardcover feeding device can be rotated at 90°, which can deliver the hard c

ase from different directions and enlarge the stamping scope.

Stamping Distance and Pressure can be Adjusted

Stamping distance and pressure can be adjusted properly within 45mm according to the different products and requirements, therefore it can be applicable

for various products in different thickness which can greatly enlarge the business scope of printing factory

Foils Adjustable

The foils feeding and collection can be adjusted as per the stamping directions,

which can reduce the foil waste and improve the usage, thus reducing the production cost.

Mechanical Position More Accurate

The whole machine is driven by the cam, which can make the position more accurately

and improve the quality, thus reducing the product waste.

Hardcover Pushing Device Controlled Independently

It can independently adjust the feeding speed as per the materials and

stamping requirements, more flexible and stable.

Equals 2-3 Times of Daily Output of the Common Stamping Machine

The stable speed is 3000pcs/h, so it can greatly improve the daily efficiency.

More Detailed Functions

ST055PE Hot Stamping Machine also has the function of automatic counting for being convenient for production management;

automatic lubrication system has reduced the daily maintenance, thus improving the production efficiency and reducing the maintenance cost, etc..

Therefore, ST has developed this automatic hot stamping machine as per the customers’

requirements for the hardcover book and packaging box, which has perfectly satisfied the

production requirements for the various stamping.

Own ST055PE Hot Stamping Machine, will inspire your new idea on hot stamping.