Why Collapsible Boxes Are Gaining Popularity

Collapsible boxes are increasingly in demand for a good reason. They can be shipped and stored flat, resulting in substantial savings in packaging and transportation costs while reducing the risk of box damage during transit. Although the production cost of collapsible boxes may be slightly higher than traditional setup boxes, their convenience and advantages make them a worthwhile option to explore.

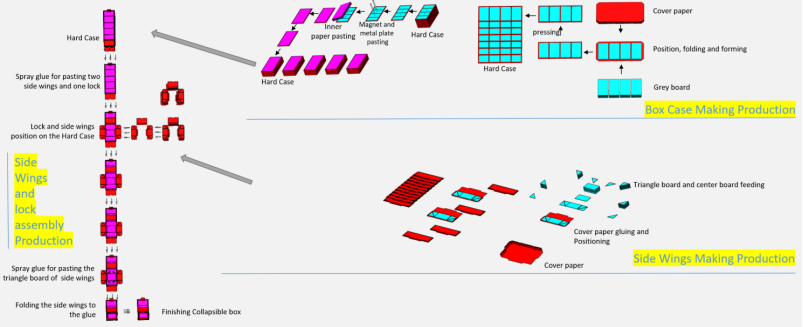

There are a few main types of collapsible boxes in today’s market. These boxes typically consist of a case with wings, and the assembly process has become more streamlined. Manufacturing collapsible containers is no longer as challenging as it once was, thanks to the availability of automated machinery. Consequently, many packaging factories have embraced automated solutions for producing collapsible boxes to enhance production efficiency and reduce manual labor requirements.

| 1 | 2 | 3 | 4 |

|  |  |  |

|  |  |  |

The production flow is as follows: